Our Solutions

01-Smart Rapid Sorting

AGV intelligent forklifts with human-to-human picking technology are suitable for the following scenarios:

- high SKU selection

- high order volumes

- frequent picking

- e-commerce logistics

- accessories warehouses

Our AGV warehouse forklifts ensure fast, accurate and efficient order fulfillment.

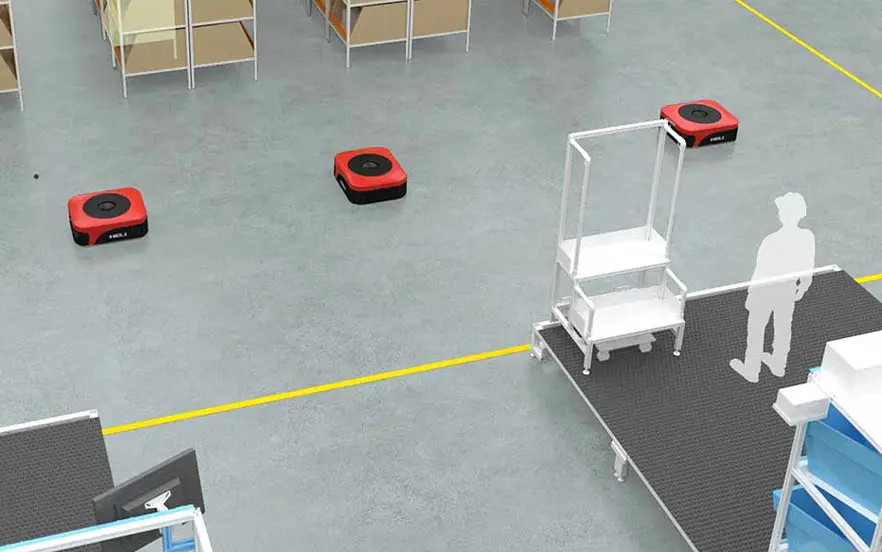

02-Unmanned Warehouse

Simplified Unmanned Storage: Intelligent handling of unmanned storage often uses AGV forklifts. Seamless transfer between workshops and warehouses does not require workpiece exchange, creating a one-step process that greatly improves storage efficiency.

- Seamless system integration: The AGV system is linked to the WMS (warehouse management system), which automatically receives operational tasks and automatically assigns them to save manpower.

- Improved warehouse management: Automated handling of AGV solutions helps to realize warehouse information management and optimizes inventory management and warehouse structure for better operational efficiency.

HELI offers types of automated guided vehicles including forward-moving, stacking, heavy-duty and handling vehicles. In addition, we provide customized AGV solutions tailored to specific user scenarios, ensuring optimal performance and adaptability to your unique needs.

03-Intelligent distribution of production line materials

- Versatile Handling Solutions: HELI AGV handling carts are designed to meet the diverse development of production scenarios and the requirements of lean manufacturing. Our AGV forklifts meet the various needs of production lines, assembly lines, transmission lines, work stations, racks and operating points.

- Intelligent logistics handling: These AGV solutions enable intelligent logistics by supporting two modes:

- – Synchronous delivery of all parts (raw materials) required for a specific part of the production line.

- – Individual parts (raw materials) are fed based on the sequence of production orders.

- Seamless task execution: Thanks to the HELI intelligent logistics handling system, our various types of AGVs can automatically perform tasks assigned by the production management system or respond to manual handling requirements.

- Increased efficiency and safety: With a stable handling rhythm and safe and reliable operation, HELI AGV forklifts significantly improve production efficiency in factories and optimize management processes.

04-Intelligent transfer of flexible line processes

- Shifting towards personalized demand: Consumer preferences tend to be personalized, small-batch, and multi-type products, leading to customization and flexibility in production methods.

- Challenges of new production modes: Frequent product changes on production lines and the need to process multiple product types simultaneously require a logistics system with high adaptability and flexibility.

- Industrial applications: Industries such as 3C electronics, light industry, and automotive, which prioritize personalized production, require flexible and intelligent logistics systems to meet current and future production needs.

- HELI Intelligent Logistics System: The HELI Intelligent Logistics System is seamlessly connected to production management systems, allowing multiple AGVs to form a flexible logistics network. It automatically assigns handling tasks and adjusts routes based on production processes, ensuring high efficiency and rapid response.

- Enhanced Collaboration: The system communicates and coordinates with on-site manufacturing and intelligent logistics equipment, supporting the transition to fully unattended manufacturing processes.

- Customizable Solutions: HELI offers a wide range of handling equipment that can be customized to specific operational needs, ensuring optimal performance and adaptability.

Collaboration process

HELIis a leading brand of industrial forklifts in China. Since our establishment in 1958, we have been focusing on the design and manufacture of high-end warehouse forklifts and equipment. In 2006, HELI achieved global recognition when it was ranked among the top 7 forklift manufacturers in the world in the "Top 20 Industrial Forklift Suppliers" list of MMH magazine.

01

Demand research

Requirements research, analysis: analysis of user operational requirements, operational processes, operational modes, preliminary program exchange

02

Schematic design

Detailed program design: detailed design of AGV logistics system (process, route, load calculation, site modification, cost, duration and other detailed programs)

03

Reach an agreement

Commercial offer, signing of technical proposal, signing of contract

04

Project Implementation

System Preparation: Vehicle Manufacturing, Software Development;

Project Construction: Site Preparation, Network Preparation;

Project Acceptance: Vehicle Intermodulation and Testing, Personnel Training, Acceptance.